Research Cluster

Solid and Fluid Simulation for Industrial Processes

Contact Point

Michele Chiumenti

Academic Leaders

Luís M. Cervera, Michele Chiumenti, Ramon Codina, Narges Dialami, Joan Baiges

External Advisors

Pär Jonsen, Karen Willcox

Research groups

- Industrial Manufacturing Processes

Michele Chiumenti - Fluid Mechanics

Ramón Codina Rovira

Overview

Staff

Projects

This Cluster develops advanced computational models for fluid mechanics and thermo-mechanical applications, specializing in additive manufacturing, friction stir welding, and complex multiphysics industrial processes.

The Solid and Fluid Simulation for Industrial Processes Research Cluster at CIMNE specializes in developing advanced computational models for complex industrial manufacturing processes. The cluster’s expertise spans two major domains: fluid mechanics simulation and thermo-mechanical simulation, employing cutting-edge numerical methods to solve challenging engineering problems.

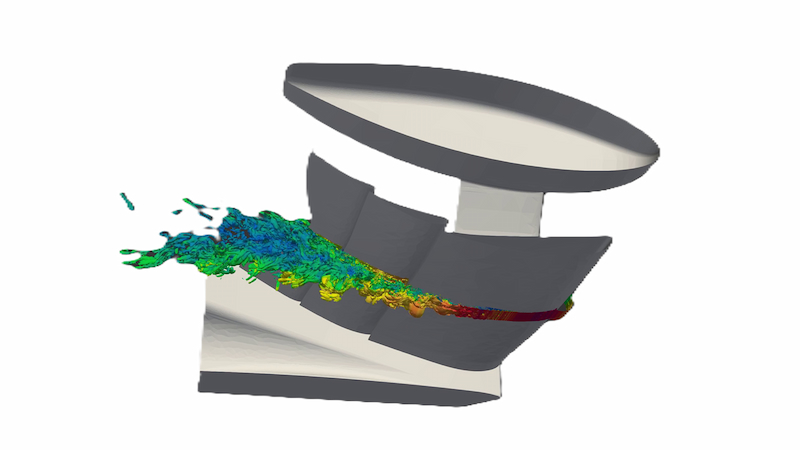

The Fluid Mechanics Group focuses on the numerical modeling of turbulent, compressible, and multiphysics flows, including fluid-structure interaction (FSI), magnetohydrodynamics (MHD), and biofluids. Their work integrates advanced finite element techniques, embedded mesh refinement, adaptive meshing, and reduced-order modeling (ROM), enabling high-fidelity simulations for aerospace design, hydraulic systems, and biomedical applications. Emphasis is placed on computational efficiency, simulation accuracy, and the transfer of fundamental research to real-world engineering problems through high-performance computing.

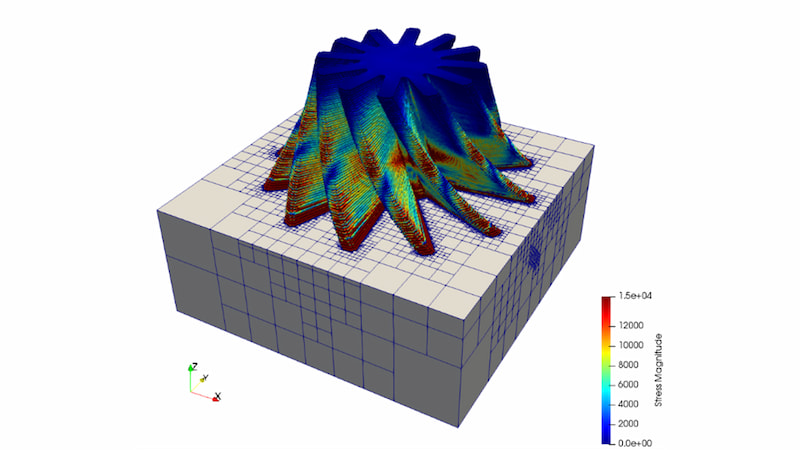

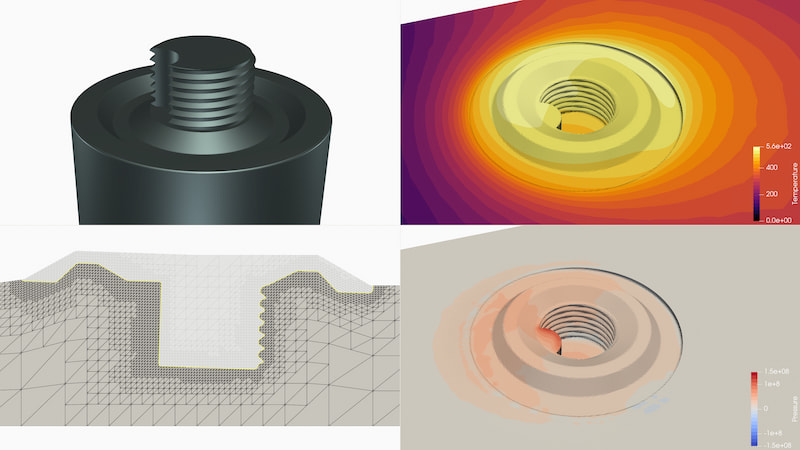

The Industrial Manufacturing Processes Group develops advanced simulation tools to model complex manufacturing operations such as casting, welding, additive manufacturing, and sheet forming. Through the implementation of high-fidelity finite element models in platforms like COMET and FEMUSS, the group enables process optimization, defect prediction, and improved material performance. Their software solutions—such as VULCAN, WELDPACK, ADD2MAN, HP4FSW, and STAMPACK—translate academic innovation into industry-ready tools used across sectors including automotive, aerospace, and heavy machinery.

Research priorities include the development of digital twins, ROM-based shape optimization using AI, and real-time control strategies for advanced manufacturing. The cluster pursues innovation through the integration of HPC, machine learning, and multiscale modeling to address process reliability, performance prediction, and sustainability in industrial applications.

Ongoing projects

Finished projects

Related news

Two CIMNE Researchers Distinguished in 2025 Academia Excellence Programme

Professor Michele Chiumenti and Professor Marino Arroyo have been awarded grants in the 2025 Academia Excellence programme, formerly known as ICREA Academia, by the Government of Catalonia. The programme, which selected 50 faculty members from the Catalan university...

Minister Sàmper visits CIMNE headquarters to explore how computational research drives industry forward

The Minister of Business and Labour, the Honorable Mr. Miquel Sàmper i Rodríguez, together with the Director General for Industry, Mr. Xavier Roca Ramón, have visited this week the headquarters of the International Centre for Numerical Methods in Engineering (CIMNE)...