Technologies Portfolio

CIMNE technologies represent the convergence of pioneering research and practical application. Our cutting-edge expertise is tailored at addressing complex challenges facing industry and society.

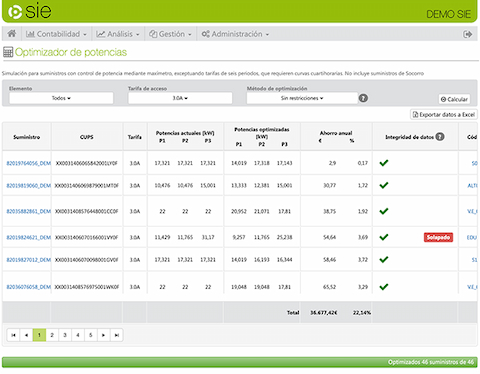

Artificial Intelligence for Urban Energy Management

AI and Big Data boost energy efficiency in cities by predicting demand, detecting anomalies, and guiding real-time decisions for smarter, greener buildings and sustainable energy systems.

Developed by the Innovation Unit in Building, Energy, and Environment (BEE Group)

This technology uses artificial intelligence and big data analysis to improve energy efficiency in urban environments. It employs neural networks and machine learning algorithms to predict energy demand, identify irregularities, and suggest optimisation strategies. These technologies, ntegrated into digital platforms, enable real-time decision-making, thereby improving energy management in buildings and communities.

This capability enables reduced consumption, the integration of renewable sources, and the adoption of decentralised self-consumption models. These tools enable administrations and energy operators to implement more sustainable and efficient strategies, thereby facilitating the energy transition in cities and industrial environments.

Digital Twins for Energy Communities

Digital twins simulate energy use in buildings and cities by combining real-time data, predictive models, and advanced analytics. Th

Developed by the Innovation Unit in Building, Energy, and Environment (BEE Group)

Digital twins that integrate real-time data, predictive models, and energy simulations to optimise energy communities. These virtual replicas allow the energy behaviour of a group of buildings to be simulated and adjusted, integrating renewable sources, storage, and shared consumption. Using technologies such as IoT, AI and BIM, predictive control environments are generated that improve overall energy efficiency, increase resilience to demand peaks and facilitate the integration of electric mobility and storage. This technology supports real-time strategic decision-making and promotes collaborative energy governance models.

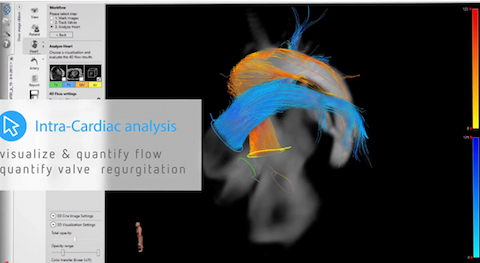

Multiscale Hemodynamic Modelling for the Cardiovascular System

Multiscale 1D–3D blood flow simulations enhance vascular diagnostics by combining systemic and local models. They support device evaluation, risk prediction, and personalised clinical planning.

Developed by the Computational Mechanics in Medical Engineering and Living Matter research cluster

Methodology that allows coupling one-dimensional (1D) models of the systemic vascular network with three-dimensional (3D) models of specific arterial segments. This multiscale approach improves the ability to accurately simulate the interaction between global conditions of the circulatory system and detailed local behaviours, such as bifurcations, stenoses or areas of clinical interest. Simulations allow the effect of implantable devices to be evaluated, pressure gradients to be estimated, and haemodynamic risk conditions to be predicted. This technology is integrated with medical images, real clinical data, and simulation environments compatible with hospital practice. Its use is geared towards translational research, personalised planning, and specialised medical training.

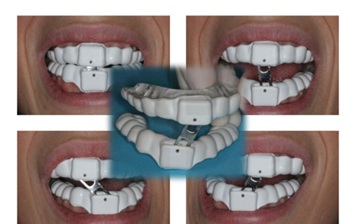

Customised Simulation of Medical Devices

AI and simulation tools enable the design of personalised medical devices by modelling patient anatomy and optimising performance. This approach enhances safety, speeds development, and supports clinical use.

Developed by the Computational Mechanics in Medical Engineering and Living Matter research cluster

This technology integrates advanced numerical models and machine learning to design medical devices tailored to the patient’s anatomy. Devices such as stents, prostheses, and mandibular advancement mechanisms are optimised using structural and physiological simulation tools. In addition, neural networks are applied to improve design performance based on clinical data and medical imaging. This customised approach increases safety, reduces development times, and facilitates regulatory validation. The clinical applicability of these technologies has been demonstrated in real healthcare settings.

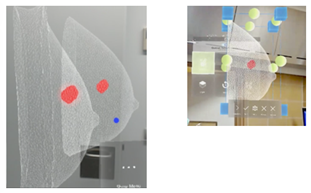

Augmented Reality-Assisted Surgery

Augmented reality and AI improve surgical planning by enabling real-time tumour visualisation through 3D models and motion tracking. This allows for better precision and safety, while taking patient-specific insights into account.

Developed by the Computational Mechanics in Medical Engineering and Living Matter research cluster

Real-time simulation tools for assisted surgery, combining customised 3D models with advanced visualisation technologies and motion capture sensors. This capability allows surgeons to visualise organs and tumours during surgical procedures, improving accuracy and reducing risks. Automatic segmentation of medical images using artificial intelligence facilitates the generation of accurate models tailored to each patient.

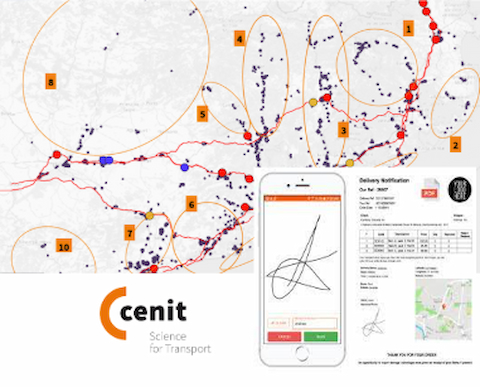

AI for Sustainable Urban Transport Planning

AI and Big Data analyse mobility patterns to improve urban transport planning, enabling smarter, greener, and more accessible cities through predictive simulations and data-driven decision-making.

Developed by the Innovation Unit in Transport (CENIT)

Big Data and artificial intelligence techniques to analyse urban mobility patterns, evaluate public policies and optimise public and private transport networks. By using data from sensors, digital platforms and simulation models, this solution contributes to the design of more sustainable cities with less environmental impact and greater accessibility. These tools also make it possible to simulate future urban scenarios, facilitating evidence-based decision-making by authorities and mobility managers. Their application improves the efficiency of transport systems and promotes more equitable and digitised mobility.

Digital Twins for Logistics and Maritime Transport

Digital twins replicate logistics and port operations in real time using AI and predictive models, improving efficiency, reducing bottlenecks, and enabling safer, smarter, and more sustainable logistics.

Developed by the Innovation Unit in Transport (CENIT)

Solutions based on digital twins to optimise logistics in ports and transport corridors. This technology allows real operations in logistics terminals and supply chains to be digitally replicated, integrating real-time data with predictive models based on artificial intelligence. It improves operational efficency, reducing bottlenecks and facilitating strategic decision-making. These tools enable critical infrastructure to be managed dynamically, while enhancing operational safety and achieving more resilient and sustainable ligistics models.

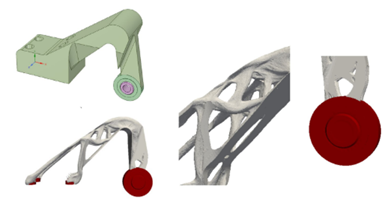

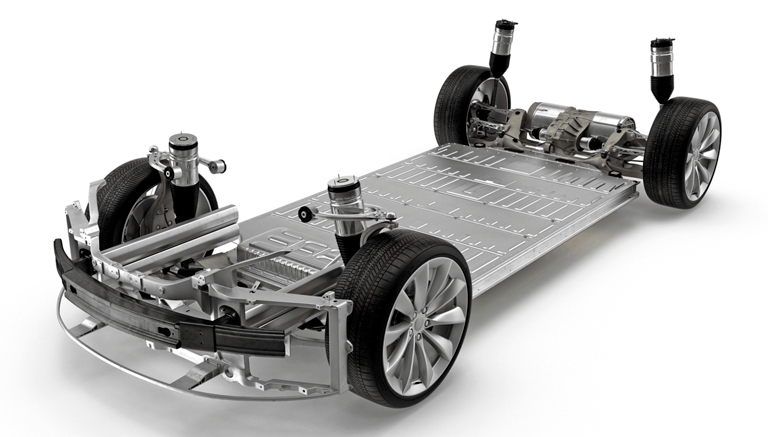

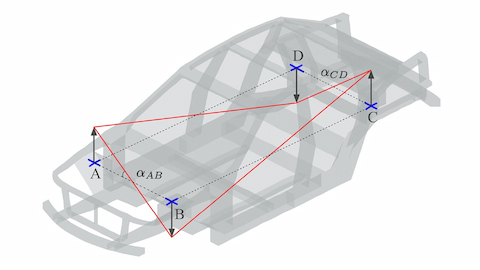

Topological Optimisation of Ultralight Structures

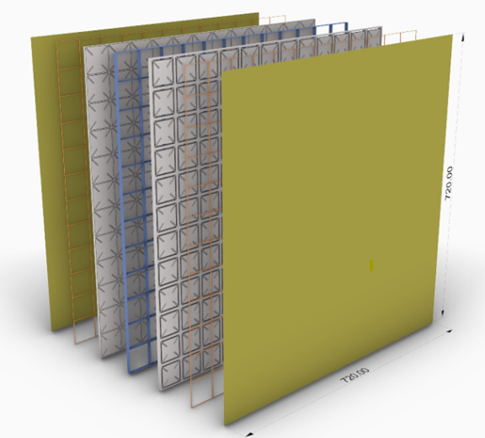

AI and simulation tools enable the design of lightweight, high-performance structures for aerospace and automotive use. This technologies reduce mass, boost efficiency, and accelerate innovation with advanced materials.

Developed by the Aeronautical, Marine, Automotive, and Energy Engineering research cluster

Topological optimisation methodologies to design structures made from composite materials that combine high mechanical performance and low weight. These technologies are applied in multiple sectors including aerospace, automotive, energy and embedded systems. Using numerical simulation tools, 3D printing and predictive models based on artificial intelligence, the “Composites and Advanced Materials for Multifunctional Structures (CAMMS)” group designs components capable of withstanding complex loads with minimal mass. This capability is key to increasing structural efficiency, reducing energy consumption and facilitating the integration of new advanced materials in industry. The methodology also allows for faster design cycles and easier structural validation in demanding environments.

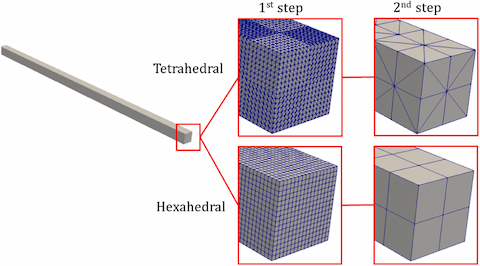

Advanced Fatigue Modelling

Numerical models for predicting fatigue failure in multi-material components in the automotive and aeronautical industries.

Developed by the Aeronautical, Marine, Automotive, and Energy Engineering research cluster

High-fidelity numerical models for simulating the fatigue behaviour of composite materials and multi-material structures. These tools enable the precise analysis of the effects of load cycles on complex components, taking into account parameters such as microstructure, geometry and service conditions. Techniques such as probabilistic uncertainty propagation (uPDF) and machine learning algorithms are applied to predict structural failures and optimise additive manufacturing processes. This technological capability enables the design of lighter, more durable and sustainable components, which are essential for industrial sectors that demand maximum reliability with reduced weight and emissions.

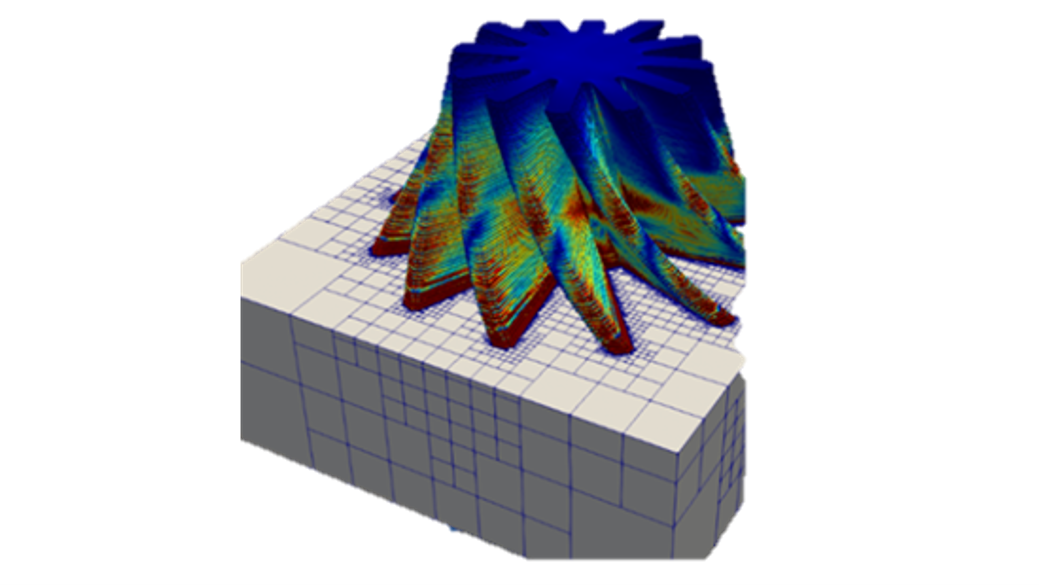

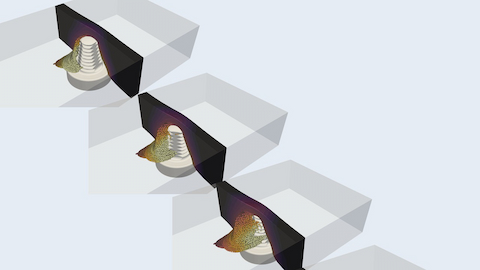

Digital Twins for Additive Manufacturing (DED)

Digital twins and AI enable real-time control of metal 3D printing, optimising DED processes by adjusting parameters dynamically. The result: better quality, less waste, and faster, smarter production.

Developed by the Solid and fluid simulation for Industrial Processes research cluster

Advanced digital twin technologies to monitor and control additive manufacturing processes using Direct Energy Deposition (DED) in real time. This capability combines physical simulations, embedded sensors, artificial intelligence and predictive models to adjust process parameters such as temperature, speed and material distribution. The system helps prevent defects, improve the quality of metal parts and reduce material waste. It also provides traceability and accelerates production in sectors with high technical requirements. This solution represents a key advance for the digitalisation of manufacturing within the framework of Industry 4.0.

Thermomechanical Simulation of Welding and Casting Processes

High-precision computational models simulate industrial processes like FSW and casting, predicting defects and residual stresses to enhance component design and reduce manufacturing failures.

Developed by the Solid and fluid simulation for Industrial Processes research cluster

High-precision computational models for simulating thermal and mechanical processes in industry, such as friction stir welding (FSW), casting, and forming. These tools enable the anticipation of defects, residual stresses and deformations, improving component design and reducing failures during manufacturing. The models are integrated into intelligent platforms that use artificial intelligence for predictive maintenance and real-time process control. This technological capability is essential for optimising production, reducing costs and increasing the reliability of critical parts in strategic sectors such as transport, energy and advanced manufacturing.

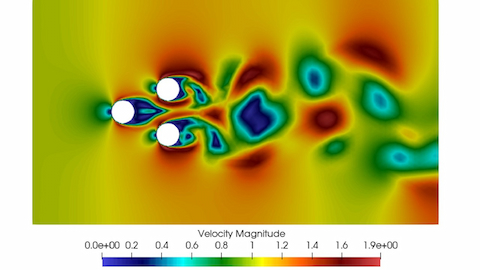

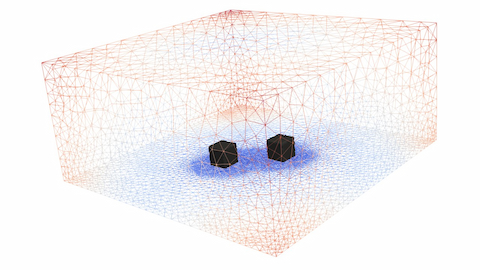

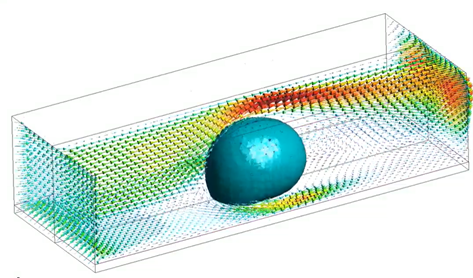

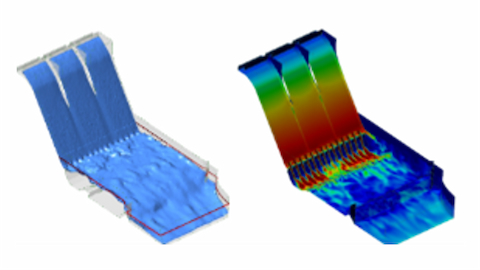

High-Precision CFD Simulation

Advanced numerical methods for CFD simulation in energy, aeronautics, and biomedicine, offering high-precision resolution of complex flows with adaptive meshing and HPC.

Developed by the Solid and fluid simulation for Industrial Processes research cluster

Advanced numerical methods for CFD (Computational Fluid Dynamics) simulation with direct application in sectors such as energy, aeronautics, biomedicine and hydraulic infrastructure. Its stabilised formulations —such as VMS, ALE and sub-scaling techniques— enable high-precision resolution of compressible and incompressible, turbulent and multiphase flows. These capabilities include adaptive meshing, fluid-structure coupling and execution in high-performance computing (HPC) environments. The tools developed are applied to complex problems such as urban ventilation, aeroacoustics, thermal design and interaction with moving structures. This technology improves predictive robustness and reduces development times in demanding engineering processes.

High-Fidelity Simulation with Reduced Models for Industry

High-precision physical simulations combined with AI optimize industrial products, offering accurate and efficient solutions for real-time control and optimization in various sectors.

Developed by the Credible High-Fidelity and Data Driven Models research cluster

The Credible High-Fidelity Modeling group addresses the main challenges of modern computational engineering: the need for highly accurate, yet efficient and credible solutions. It develops complex physical models with guaranteed numerical accuracy, combined with order reduction techniques (ROM) that allow multiple parametric queries to be answered in computationally viable times. This capability is key in contexts such as real-time control, inverse analysis, or optimisation. The group’s approach integrates data science, scientific machine learning, and uncertainty quantification techniques to build hybrid physical-digital models with traceability and numerical validity. These are applied in sectors such as energy, healthcare, advanced manufacturing, and transport.

Credible Digital Twins with Uncertainty Quantification

Digital twins with predictive quality control integrate experimental data and high-fidelity simulations, enhancing decision-making across multiple industries.

Developed by the Credible High-Fidelity and Data Driven Models research cluster

Digital twins focused on the credibility and traceability of their predictions. It integrates experimental data with high-fidelity simulations using Bayesian inference, data assimilation methods, and numerical error control. These techniques allow complex physical systems to be represented reliably, explicitly quantifying the uncertainty associated with each prediction. Applications include the design and evaluation of biomedical devices, infrastructure monitoring, structural failure prediction, and industrial system optimisation. This approach increases confidence in models, improves decision-making, and strengthens technology transfer in demanding environments.

Intelligent System for the Prevention of Silent Drowning

AI and computer vision technology for real-time detection of drowning risks in coastal environments, enhancing lifeguard response and swimmer safety.

Developed by the Pre, Post, and Digital Technologies (DIGIT) innovation unit

This technology, based on artificial intelligence (AI) and computer vision, allows for automatic surveillance of bathing areas on beaches. This system is designed to detect situations of silent drowning in real time, a phenomenon that can go unnoticed in open spaces where human supervision is limited. The solution continuously analyses images captured by cameras located at strategic areas, identifying behaviour patterns that indicate danger, such as abnormal immobility, progressive sinking or loss of orientation. The system generates instant alerts that allow lifeguards to intervene quickly and accurately, increasing the chances of saving lives. This technology represents a significant advance in the protection of swimmers in natural environments and can be adapted to other situations where AI-based preventive surveillance is critical.

IoT + Blockchain Platforms for Traceability and Real-Time Monitoring

Smart platforms integrating IoT and blockchain for secure, real-time traceability and monitoring in industrial environments, ensuring data integrity and operational efficiency.

Developed by the Pre, Post, and Digital Technologies (DIGIT) innovation unit

The CIMNE TIC Group has developed smart platforms that integrate IoT sensors and blockchain technology to provide real-time traceability, monitoring and validation. These platforms capture and record physical data — such as temperature, position, vibration or consumption — and store it securely using decentralised architectures. The combination with NFC technologies, 3D visualisation and advanced analytics enables efficient interaction between the physical and digital worlds. These technological capabilities are aimed at transforming production, logistics and energy processes, ensuring transparency, data integrity and operational efficiency in strategic sectors.

Digital Infrastructure for Electromobility and Distributed Energy

GIS platforms for planning and managing electric vehicle charging networks, optimizing locations and integrating IoT for real-time monitoring in rural areas.

Developed by the Pre, Post, and Digital Technologies (DIGIT) innovation unit

The CIMNE TIC group has developed technologies for the planning and operation of charging networks for electric vehicles, especially in rural contexts or areas with low population density. The solutions include GIS platforms to map and simulate energy demand, predictive models to optimise the location of charging points and IoT technologies for real-time monitoring. They also integrate with local renewable energy systems and energy storage. This digital infrastructure enables the planning of more equitable, efficient and resilient electromobility networks, facilitating the energy transition and improving access to sustainable mobility across the territory.

Open Source Platform for Advanced Multiphysics Simulation

Multiphysics simulation platform with HPC and AI for modeling complex phenomena, enabling faster and accurate solutions in various sectors.

Developed by the Large Scale Multiphysics Computations research cluster

KRATOS is a multiphysics simulation platform developed by CIMNE, which allows modelling complex phenomena such as fluid-structure interaction, thermal dynamics, electromagnetism and more. Its flexible design allows combining different numerical methods, integrating customised models and adapting to the specific needs of sectors such as infrastructure, energy, manufacturing or health. It incorporates high-performance computing (HPC), order reduction (ROM/HROM) and artificial intelligence capabilities, enabling it to solve highly complex non-linear problems faster and more accurately. Its use extends to both academic and industrial environments, facilitating the development of digital twins and predictive engineering solutions.

Digital Twins Executable in Edge Computing (SimTwins)

Edge computing digital twins for real-time predictive maintenance and control, combining multiphysics simulation and AI for low-latency, reliable decision-making in local devices.

Developed by the Large Scale Multiphysics Computations research cluster

This technology that allows digital twins to be executed directly on local devices (edge computing), close to the physical system to be monitored or controlled. This technology combines multiphysics simulation, order reduction techniques and artificial intelligence (AI) to generate real-time predictions with low latency, without relying on connectivity to remote servers. It is especially useful in applications such as turbines, electric motors or autonomous systems, where immediate and reliable decision making is required. This capability enables the implementation of predictive maintenance strategies, operational optimisation and autonomous control in complex systems, even in environments with limited computational resources.

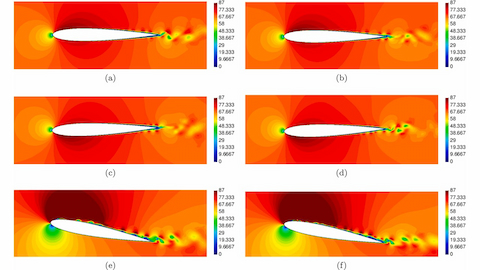

Aeroacoustic Simulation and Turbulent Flow for Industrial Engineering

High-precision models that simulate turbulent flows and acoustics to optimize airfoils, reducing noise and improving efficiency in aeronautics and automotive sectors.

Developed by the Solid and fluid simulation for Industrial Processes research cluster

Advanced models to simulate turbulent flows, acoustic wave propagation and fluid-structure interaction phenomena. These simulations allow the aerodynamic behaviour of components to be analysed and optimised under real operating conditions, contributing to the design of quieter and more efficient solutions. Stabilised finite element formulations, adaptive meshing and multiphysics coupling techniques are employed, together with high-performance computational tools. These capabilities are applied in sectors such as aeronautics, automotive and environmental acoustics, allowing for reduced noise impact, improved energy efficiency and increased accuracy in aerodynamic design.

Thermo-Mechanical Analysis of Industrial Processes

Thermomechanical models simulate industrial processes to predict stresses and deformations in forging and 3D printing, improving design and structural performance.

Developed by the Solid and fluid simulation for Industrial Processes research cluster

Numerical techniques for modelling industrial processes involving large deformations, heat transfer and microstructural evolution. These simulations allow the prediction of residual stresses, deformations and structural behaviour in metal parts subjected to manufacturing processes such as forging, 3D printing or heat treatments. Advanced formulations – such as level-set methods, embedded techniques and adaptive refinement – are used to capture critical areas in complex geometries with high accuracy. These capabilities improve process design, reduce manufacturing errors and optimise the structural performance of large-scale industrial components.

Intelligent Control of Microfluidic Processes

AI-driven control systems optimize real-time material deposition in microfluidics by adjusting flow rates, temperature, and droplet trajectories for precision manufacturing of sensors and chips.

Developed by the Solid and fluid simulation for Industrial Processes research cluster

The Fluid Mechanics research group developed an advanced control system based on artificial intelligence for the management of material deposition processes in the field of micro and nanofluidics. This technology allows critical parameters such as flow rate, temperature, electrical charge and microdroplet trajectory to be adjusted in real time, optimising coating quality and reducing material waste. The solution is aimed at high-precision applications in the manufacture of devices such as sensors, chips, biochips and photonic components. In addition, the system incorporates predictive capabilities to implement preventive maintenance and increase the overall efficiency of the deposition equipment.

Advanced Thermal Management for High Performance Chips

Multiphysics simulations that fluid flow, heat transfer, and mechanical stress analysis to design optimized microfluidic cooling systems for high-performance semiconductor packages.

Developed by the Solid and fluid simulation for Industrial Processes research cluster

The Fluid Mechanics research group at CIMNE has developed coupled multiphysics models to predict and control heat buildup in high-performance electronic devices. The simulation integrates microfluidic flow, heat transfer and mechanical stresses, enabling the design of cooling solutions tailored to chip packages and network systems. Microfluidic channels are developed and integrated directly into the package structure, improving thermal dissipation without compromising the integrity of the device. This technological capability is key to extending the lifetime, increasing energy efficiency and improving the thermal performance of electronic components used in sectors such as telecommunications, artificial intelligence or data centers.

3D numerical modeling for urban excavations

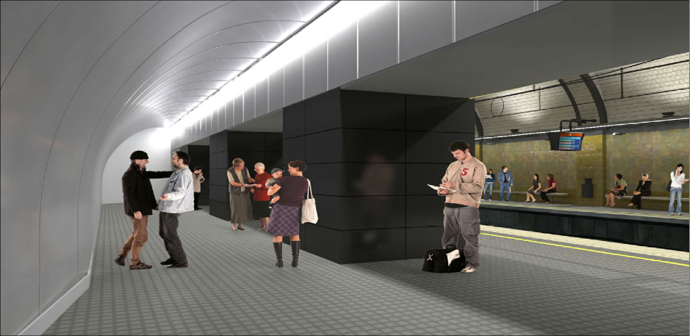

3D finite element models simulate urban excavation impacts on surrounding structures, predicting settlements and deformations to optimize subway construction safety and design decisions.

Developed by the Geomechanics and Hydrogeology research cluster

Advanced three-dimensional numerical modeling capabilities to analyze the impact of excavations in dense urban environments. Finite element simulation tools and advanced constitutive formulations are used to represent the interaction between complex soils and structures such as buildings, diaphragm walls or deep foundations. This approach allows predicting settlements, deformations and structural responses to different construction phases. Validation is performed using data obtained by in situ instrumentation and the model adapts to different geometries and geotechnical conditions. This technology is essential for planning subway works safely, minimizing risks and optimizing design decisions in urban infrastructure projects.

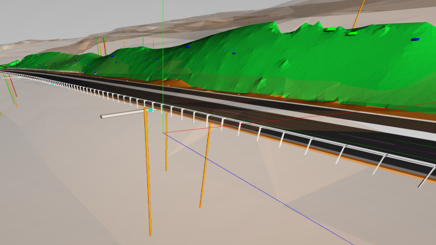

Technologies for Monitoring and Management of Unstable Slopes

Integrated slope monitoring that combines in-situ sensors, satellite InSAR, and 3D geotechnical modeling to predict landslides, enabling early warning systems for infrastructure protection.

Developed by the Geomechanics and Hydrogeology research cluster

The Geomechanics research group at CIMNE offers technological capabilities for the monitoring and management of unstable slopes, aimed at reducing geotechnical risks in critical infrastructure. These capabilities include the integration of in situ sensors (such as inclinometers, piezometers and optical prisms), geospatial analysis with satellite radar techniques (InSAR), and 2D and 3D geotechnical modeling to simulate deformation and collapse scenarios. In addition, data analysis systems are used to establish early warning thresholds and facilitate real-time decision making. These technologies make it possible to continuously characterize ground stability, anticipate landslide events and plan reinforcement or mitigation interventions. They are applicable both to linear infrastructures (roads, railroads) and to urban or industrial areas at geological risk, contributing significantly to resilience to natural events and climate change.

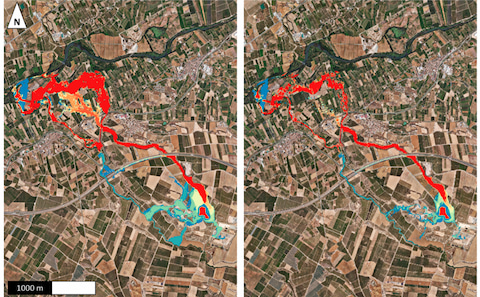

Hydraulic Early Warning Systems

Real-time flood prediction systems that integrate hydraulic models with meteorological data and satellite imagery to generate automated early warnings and support emergency response planning.

Developed by the Machine Learning and Models in Hydro-Environmental Engineering research cluster

The FLUMEN group works in the design and implementation of early warning systems that integrate hydraulic and meteorological models with real-time data from hydrological stations, remote sensors and satellite images. These platforms make it possible to anticipate floods in complex watersheds, dynamically model water behavior and generate alerts in an automated manner. Visual 2D and 3D interfaces are used to facilitate data interpretation by emergency services and responsible administrations. These technologies reinforce the capacity to respond to extreme events and enable more effective planning of mitigation and evacuation measures, improving the resilience of territories in the face of hydrometeorological phenomena.

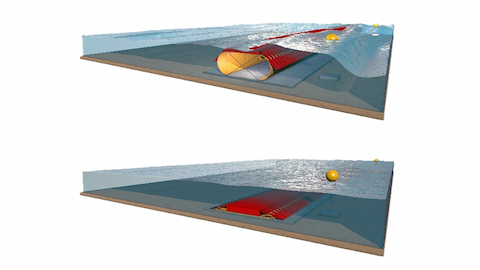

Inflatable Breakwaters for Coastal and River Protection

Adaptive inflatable breakwaters deploy or retract based on flow conditions to control erosion, manage sedimentation, and restore river environments without permanent rigid infrastructure.

Developed by the Structural and Particle Mechanics research cluster

Innovative solutions based on inflatable breakwaters, flexible structures that deploy or retract according to flow conditions or environmental requirements. These systems make it possible to modulate water flow, reduce erosion processes, control sedimentation and facilitate navigability without the need for permanent rigid infrastructures. They are made of resistant materials, reversible installation, and can be remotely operated to dynamically adapt to extreme events or seasonal variations. This solution represents a sustainable and efficient alternative for the integrated management of rivers, coasts and estuaries, contributing to ecological restoration and adaptation to climate change.

Dam Engineering and Predictive Management of Reservoirs

AI-powered hybrid models that combine neural networks with hydraulic simulation to optimize dam operations. This predicts flows and automatizes discharge strategies for enhanced water safety.

Developed by the Machine Learning and models in Hydro-Environmental Engineering research cluster

Hybrid models that combine artificial intelligence and hydraulic simulation to optimize the operation of dams and reservoirs in complex and variable contexts. Neural networks, supervised learning algorithms and time series analysis are integrated to predict flows, demands and critical hydrometeorological conditions. These tools allow automating operational decisions under uncertainty, adjusting discharge strategies and maximizing efficiency in water resource management. This improves structural safety, strengthen resilience to extreme events and facilitate adaptive planning based on data and simulation.

Meta-Materials for Advanced Acoustic Control

Computational design of acoustic meta-materials that uses periodic geometric configurations to create selective sound attenuation zones, enabling lightweight high-performance noise control.

Developed by the Mechanics of Advanced Materials and Metamaterials research cluster

This technology allows for the production of acoustic meta-material capable of attenuating sound propagation thanks to computationally designed periodic geometric configurations. These structures make it possible to generate selective attenuation zones and increase the acoustic insulation capacity without the need to significantly increase the mass or volume of the material. Multi-scale models and homogenisation techniques are applied to predict the dynamic behaviour of the materials from their microstructure to their integrated functional response. This enables the design of high-performance acoustic solutions adapted to specific requirements in sectors such as building, mobility, aerospace and product design, where noise control is critical and must be combined with lightness and structural efficiency.

Want to learn more?

Discover how CIMNE's cutting-edge innovation can tailor to the needs of your organization

Contact us