HP4FSW leverages the expertise of CIMNE’s research cluster in Solid and Fluid Simulation for Industrial Processes, a highly-specialized team of researchers with a solid background, focusing on developing advanced computational models with direct industrial applicability.

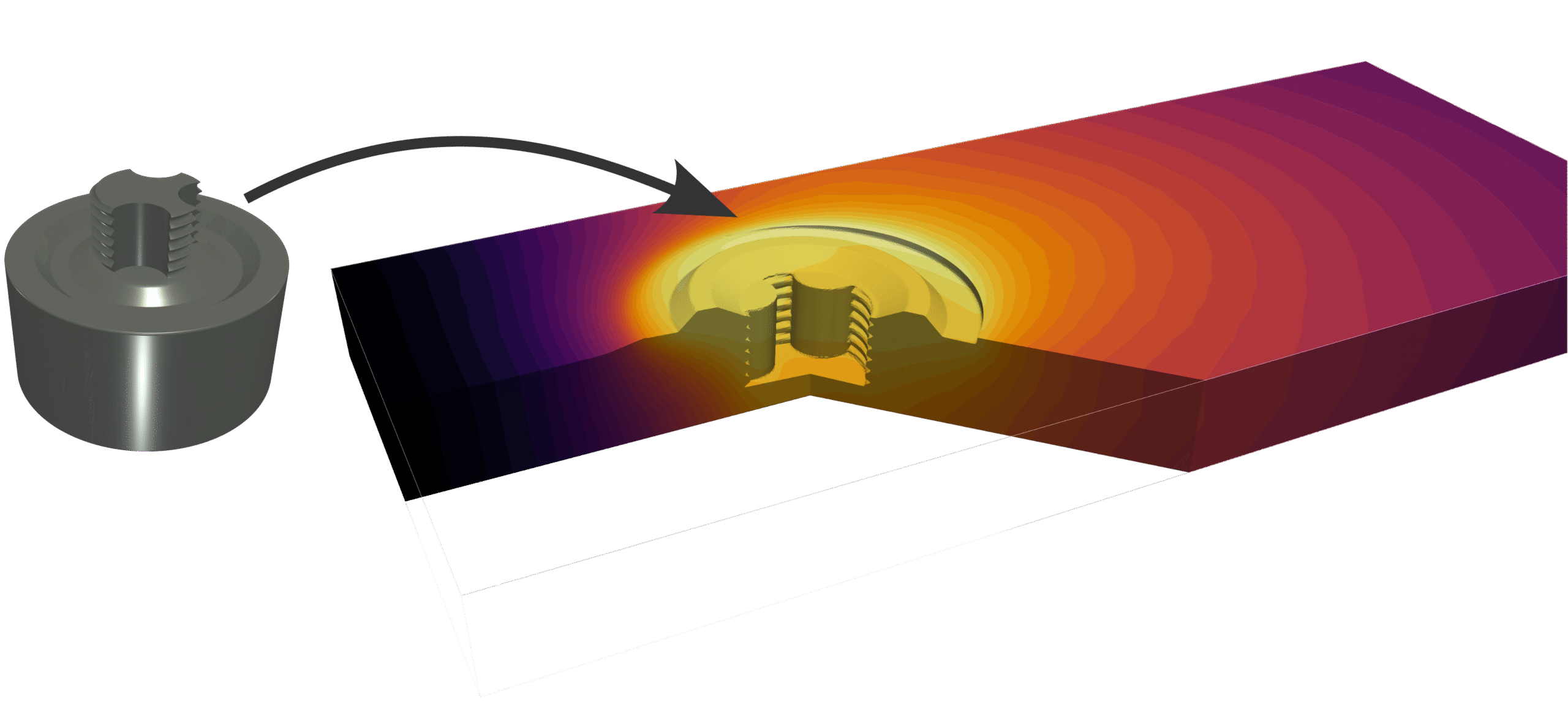

HP4FSW is a high-performance simulation tool developed at CIMNE for the analysis and optimization of Friction Stir Welding (FSW) processes in industrial environments. Designed for integration with HPC systems, it enables accurate and efficient modelling of both thermal and mechanical aspects of the process, significantly reducing simulation time while ensuring predictive reliability.

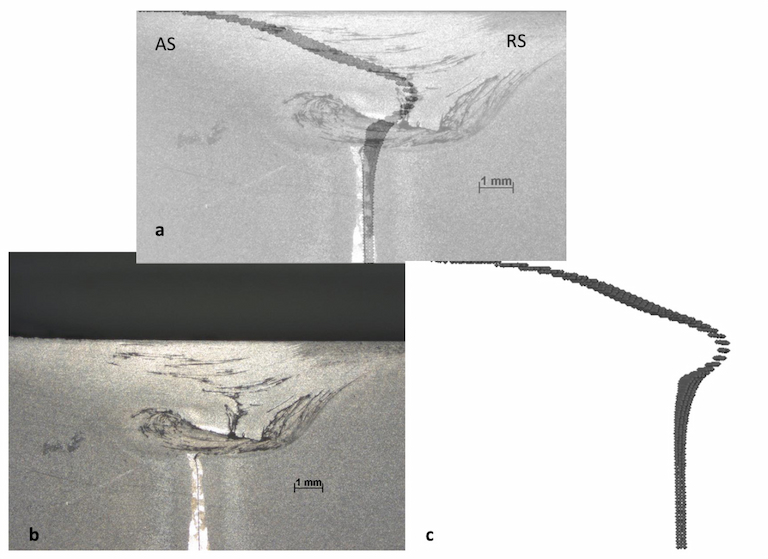

The platform provides detailed modelling capabilities, covering complex tool geometries, tool tilt angle, and key process features such as frictional and plastic heat generation, thermal dissipation, and material flow. It also incorporates a particle-tracking module to simulate material trajectories, allowing prediction of internal defects such as oxide line propagation, voids, and tunnel defects before physical validation.

HP4FSW serves industries including automotive, aerospace, rail, and shipbuilding. By facilitating early defect detection and process optimization, it contributes to improved weld quality, shorter development cycles, and lower manufacturing costs.

In action

Features

Faster simulations through full HPC integration

Accurate modelling of complex tool geometries

Improved weld quality and defect reduction

Lower material waste and energy consumption

Applications

Automotive welding optimization

Aerospace structural joints

Naval and shipbuilding components

Manufacturing with advanced materials

Interested?

If you want to learn more about our FSW expertise or how we can help your organization, send us an email!

Discover CIMNE’s research cluster in Solid and Fluid Simulation for Industrial Processes