Large Scale Multiphysics Computations

Intelligent Multiphase Modeling in Microsystems IM³

Principal Investigator

Pavel Ryzhakov

Overview

Research

Staff

Projects

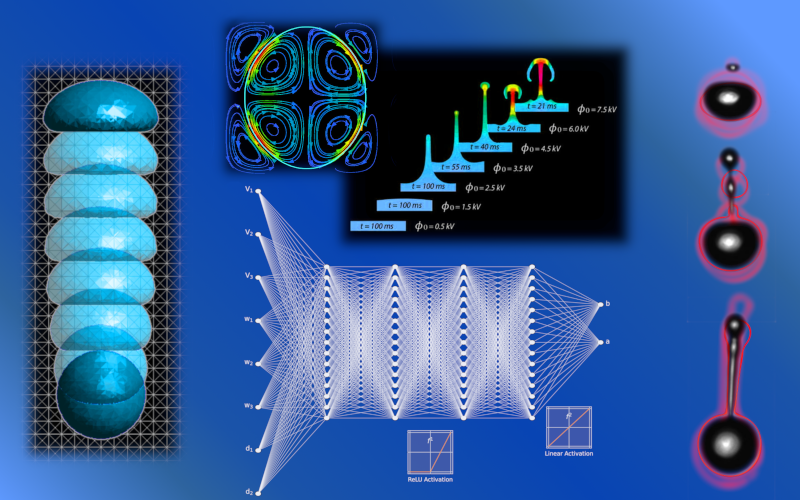

The IM³ group advances research in multiphase flow modelling, with a particular focus on microsystems. It combines numerical simulations with experiments and AI to tackle real-world challenges.

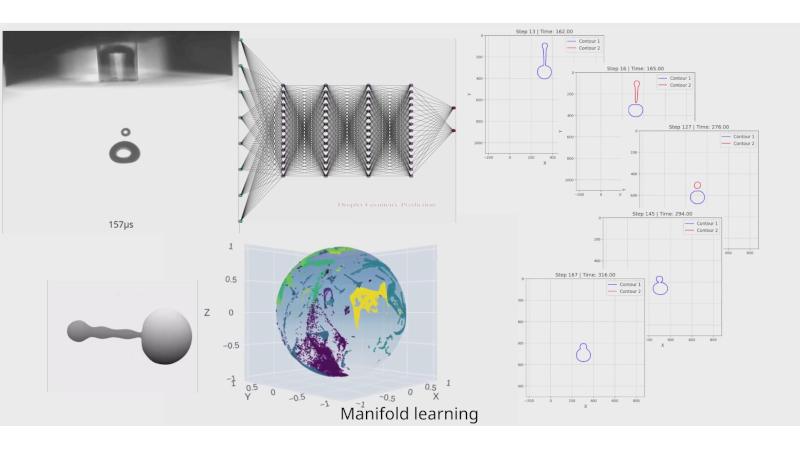

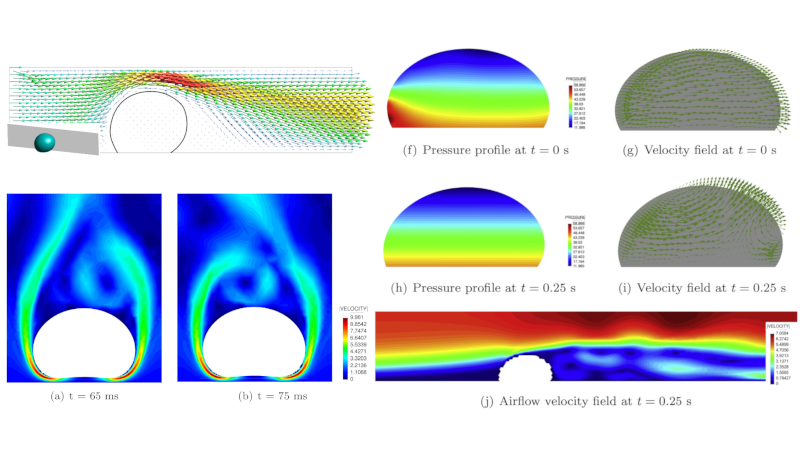

The Intelligent Multiphase Modelling in Microsystems (IM³) group, led by Dr. Pavel Ryzhakov, is dedicated to advancing research in multiphase flow modelling, with a particular focus on microsystems. The group develops and enhances cutting-edge computational models tailored to address the unique challenges of microfluidic environments, bridging the gap between fundamental research and practical engineering solutions. IM³’s integrated approach combines state-of-the-art numerical modeling, experimental studies, and artificial intelligence, reflecting the complexity of real-world systems and enabling deeper insights into underlying physical phenomena.

Droplet dynamics is central to the group’s work, with the development of innovative computational models and simulations of free droplets, droplet generation, wetting behavior, and multi-droplet interactions. Substantial effort is also dedicated to the development of techniques for simulating the propagation of multiphase flows in complex and/or porous media. Artificial intelligence enhances our activities, laying the groundwork for digital twins and smart control systems for microfluidic devices. IM^3’s projects span digital manufacturing, inkjet printing, water purification, fire safety, and fuel cell water management, delivering innovative, sustainable solutions.

Ongoing projects

Finished projects

Related news

No Results Found

The page you requested could not be found. Try refining your search, or use the navigation above to locate the post.