|

2011-2014. Ultra low cycle fatigue under high strain loading conditions

Project developed in partnership with FEUP, CSM, OCAS N.V., UThessaly, RWTH, UPisa and SZMF. This project consisted in the numerical simulation of pipelines subjected to both internal pressure and variable cyclic displacements. To achieve this purpose, CIMNE has developed a new isotropic hardening law, to simulate Ultra Low Cycle Fatigue. The model developed is based on the Barcelona model originally formulated by Lubliner et al. Although this model was originally defined to simulate brittle materials such as concrete, here is used with a kinematic and isotropic hardening law specifically defined for the simulation of steel. One of the main characteristics of the model is that the isotropic hardening behavior of the material is driven by the plastic energy dissipated: the model measures the fracture energy that is dissipated as the plastic strain increases, and this energy is used to define the plastic strain level at which material softening due to damage starts and finishes. The model considers that damage initiates when the plastic law reaches the softening region and the complete failure is obtained when all fracture energy of the material is dissipated. The model it capable of simulating material failure due to Ultra Low Cycle Fatigue by its own, without the need of any other damage variable computed independently of the plastic formulation. The proposed approach is not only capable of predicting material failure for regular and non-regular cyclic loads, but it is also capable of coupling cyclic loads with monotonic loads, which allows to predict that the structure will fail sooner if the monotonic load is applied after several hysteresis cycles, than if these cycles are not applied. This capability is obtained as a consequence of the fact that the material failure is predicted by the plastic non-linear constitutive equation itself. Another advantage of the formulation proposed is that it is capable of using any yield and potential surfaces to characterize the material, which increases its applicability to different steel alloys.

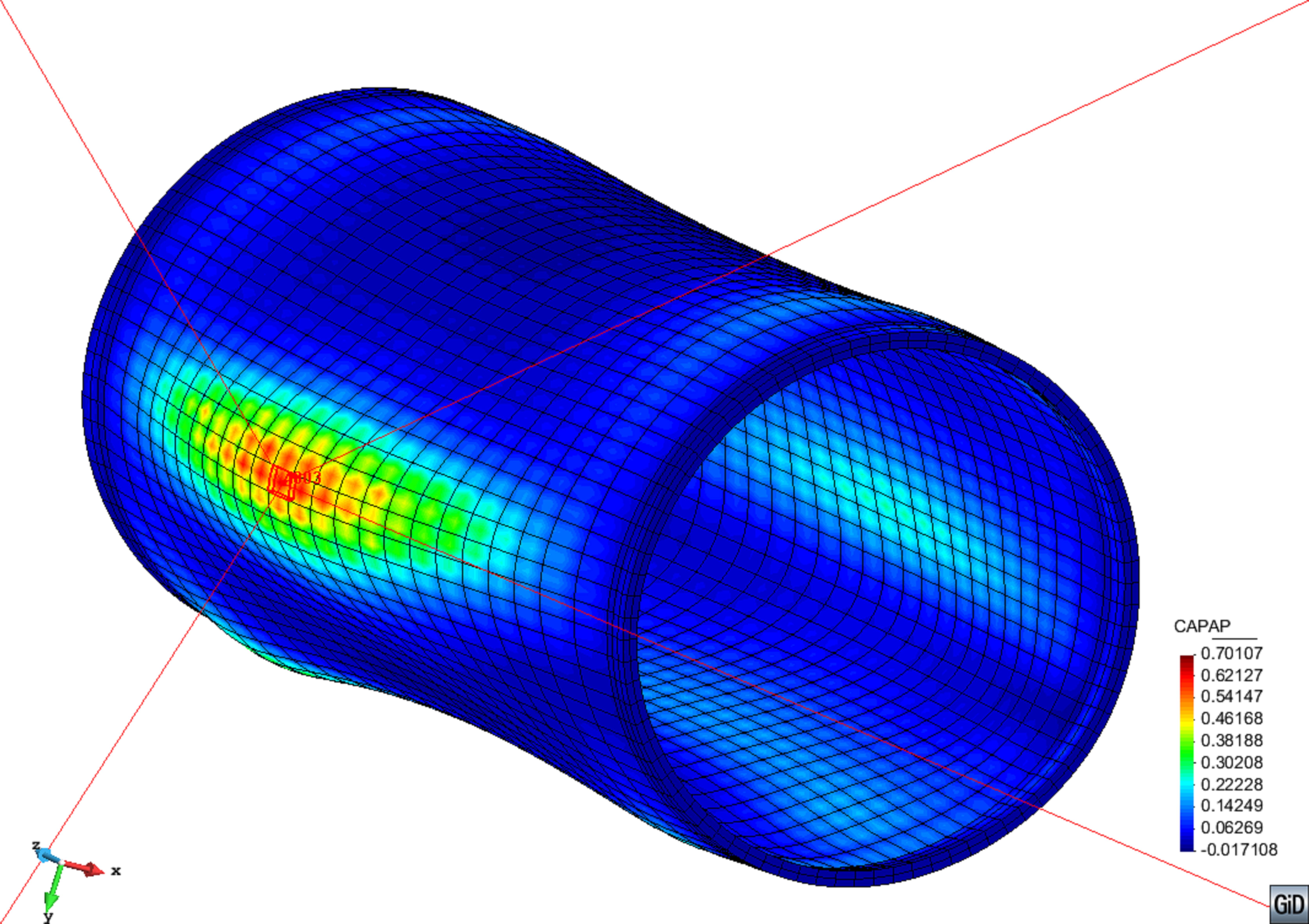

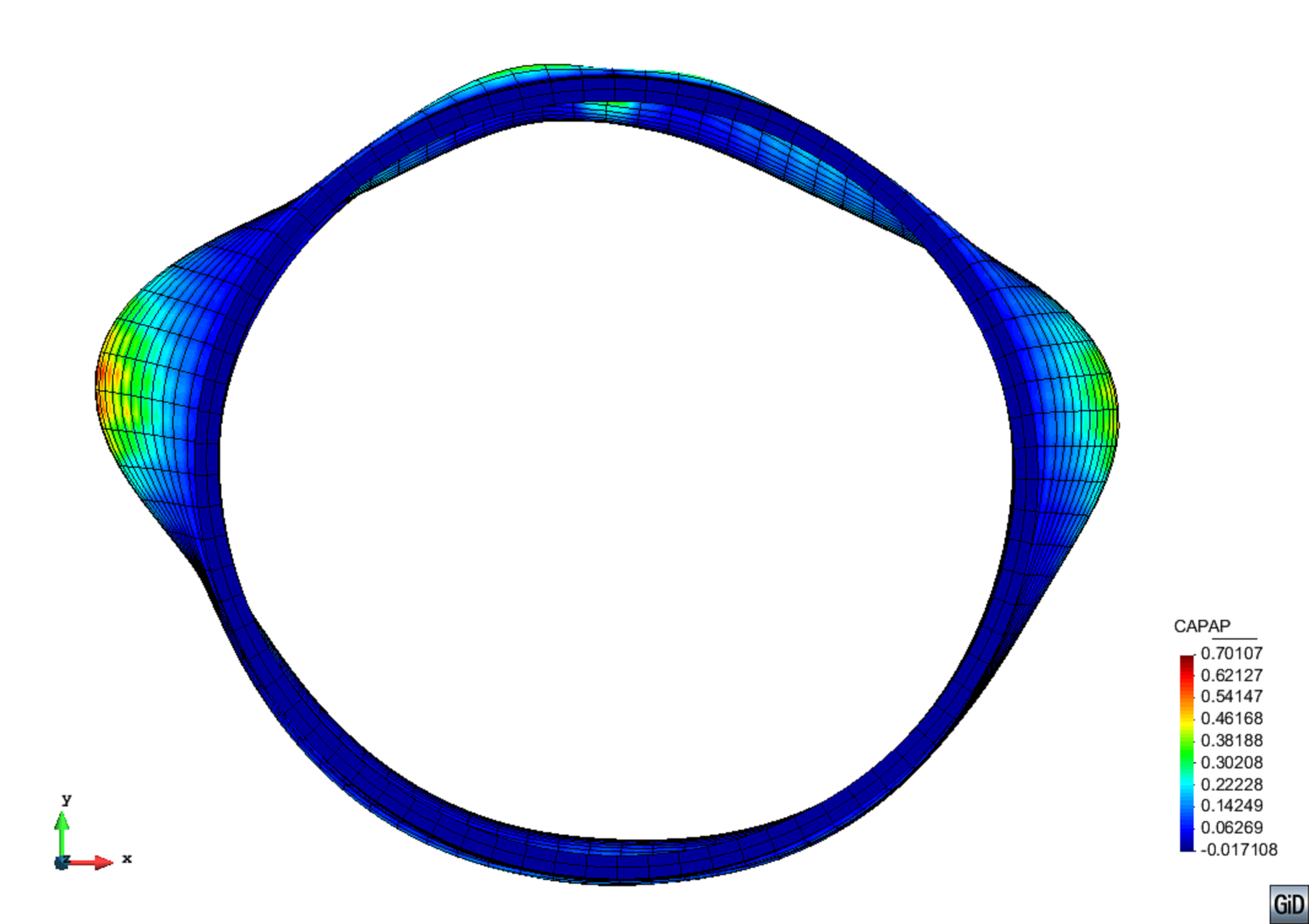

View of the deformed shape at the end of the analysis for a straight pipe subjected to a fixed axial displacement and monotonically increasing pressure until burst. |

|